Prefabricated House

- Home

- Our products

- Steel Structure

- Prefabricated House

The Advantage Of Steel Structure Prefabricated House:

1. Stable structure: Safe and reliable light steel flexible structure system.

2. Beautiful decoration: Beautiful materials, bright color, flat surface and art decoration.

3. Flexible composition: Doors and windows could be installed at any position, separate wall could be built at any transverse axis.

4. Easy & quick to install: Repeated use, simple tools for installation. One worker could install 20-30 square meters per day, 6 workers could work out 3K×10K house in two days.

5. Economical: Compared with concrete buildings, it costs much less.

6. Long life span: All the outside steel structure is galvanized, anti-rust, which makes its using life more than 10 years.

7. Environmental friendly: Professional design, easy installation, recycling use, no construction waste.

8. Extensive application: Construction site, office building, family living house, school, dormitory, canteen, recreation room, washing room, bathroom, outdoor temporary building, etc.

1. Energy Saving, Excellent Performance |

|

Heat Preservation |

Major material for wall panel is anti freezing,heat preserving and environmental friendly. |

Heat Insulation |

Adjust the indoor temperature at a constant range. |

Fire Proof |

Both face sides with 4.5mm calcium-silicon fire proof boar,thus DQ EPS and Cement panel can be against a high temperature of 1000°C for 4 hours. |

Water Proof |

Tests has proved that water containers can be made by DQ EPS and Cement panel without absoring functions and no eakage at all. |

Sound Insulation |

The inside of DQ wall panel material(EPS polystyrene grain)has fine sound insulation and sound-absorbing functions. |

2. Easy Construction Process |

|

Easy to Install |

Using our installation material(PU Foam and Cement Adhesive)is easy to build house. |

Shorter Time |

For a 50sq. house,using DQ EPS and Cement sandwich wall panel,three peole can finish it within ONE day,while using traditional block,it will take at least SEVEN days with ONE WEEK to finish. |

3. High Security performance |

|

High Intension |

DQ EPS and Cement sandwich wall panel can be nailed directly or have expansion bolt to lift and hang heavies,it can be covered by ceramic tile,wall paper,wood panel,coating etc. |

Earthquake Resistance |

The Seismic performance of DQ EPS and Cement sandwich wall panel is at a magnitude of 8.5. |

4. Space and Cost Saving |

|

Space Saving |

DQ EPS and Cement sandwich wall panel with the thickness of 60mm~180mm,as athin and solid new type construction material,it will save lot of construction space compared with the traditional block. |

Labor Cost Saving |

As DQ wall panel is easy and fast to construct. |

Foundation Cost Saving |

As the weight of DQ wall panel is only 1/12 of traditional block,it will save 2/3 cost on construction structure. |

Specifications of Steel Structure Hangar:

1. Columns and beams

Material Q345 or Q235 Steel, Straight or Variable cross-section

2. Bracing

X-type or V-type or other types bracing made from round, angle pipes etc.

3. Purlin

C or Z type: Size from C120~C320, Z100~Z200

4. Wall and roof panels

Single Colorful Corrugated Steel Sheet

Sandwich panels with EPS, Rock cotton, fiber glass, PU etc.

5. Bolts

High Strengthen Bolt, Normal Bolt, Post feet Bolt.

6. All Accessories

Skylight Belts, Ventilators, Down Pipe, Rolling or Sliding Door, PVC or Aluminum Alloy Windows, Gutter etc.

7. Surface

Two lays of Anti-rust Paint

Option size | 20ft, 40ft, etc... We also had special size for 2.9M height |

Main material |

Galvanized steel structure with sandwich panel wall and doors, windows, etc. |

Weight |

3200kgs |

Service life |

30-40 years |

Color |

White, blue, green, brown, or customized |

Steel structure |

3mm Hot galvanized steel structure with 4 corner casts and

|

Columns |

3mm Hot galvanized steel structure |

Wall |

50/75/100mm EPS/Rock wool/PU Sandwich Panel |

Roof |

3-4mm Hot galvanized steel structure with 4 corner casts and

|

Door |

Made of steel/aluminum frame

|

Window |

Made of PVC/aluminum fame. |

Connection kits |

PVC Connection kits for ceiling, floor and walls. |

Electricity |

3C/CE/CL/SAA Standard,with distribution box, lights, switch, sockets, etc. |

Optional Accessories |

Furniture, sanitary, kitchen, A/C, electrical appliance for accomodation, office, dormitory, toliet, kitchen, bathroom, shower, steel roof, cadding panels, decorative material, etc. |

Advantage |

(1) Fast installation: 2 hours/set, save labor cost;

|

Steel Structure Material:

1. Columns and beams

Material Q345 or Q235 Steel, Straight or Variable cross-section

2. Bracing

X-type or V-type or other types bracing made from round, angle pipes etc.

3. Purlin

C or Z type: Size from C120~C320, Z100~Z200

4. Wall and roof panels

Single Colorful Corrugated Steel Sheet

Sandwich panels with EPS, Rockwool, fiber glass, PU etc.

5. Bolts

High Strengthen Bolt, Normal Bolt, Post feet Bolt.

6. All Accessories

Skylight belts, Glass curtains, Ventilators, Down pipe, Rolling or Sliding door, PVC or aluminum alloy windows, Gutter etc.

7. Surface

Two lays of Anti-rust Paint

Design

1. Our company has an experienced design team, more than 8 senior engineers.

2. We use professional design software which can ensure the safety of products and control the amount of materials accurately and reduce the cost.

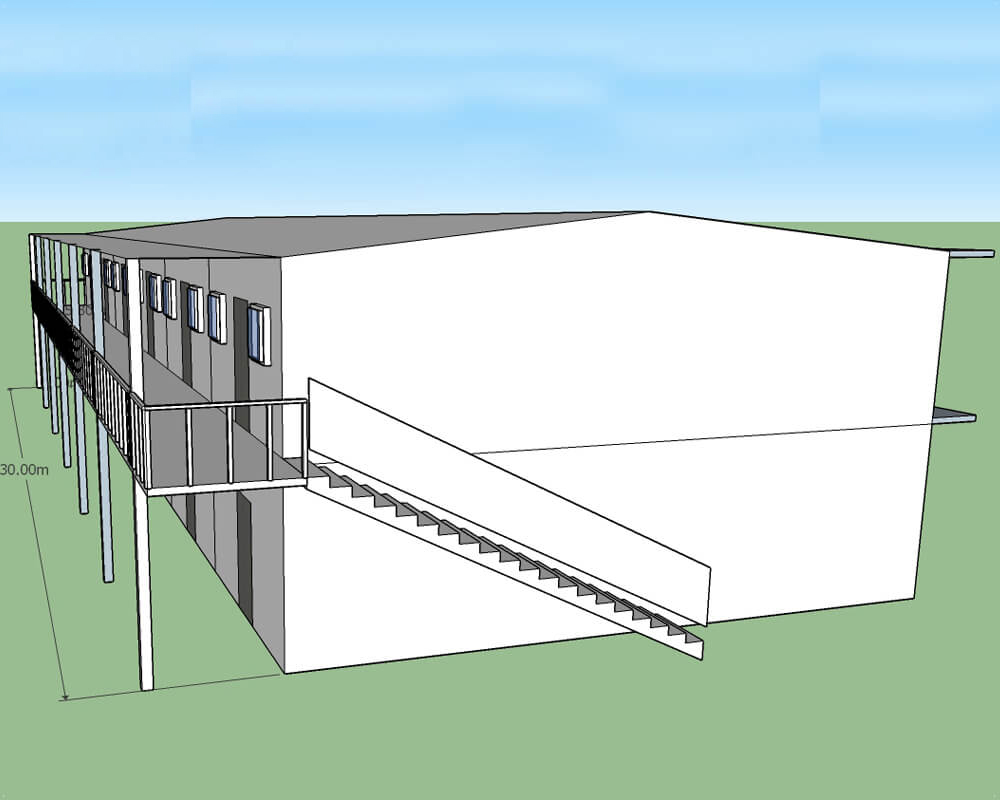

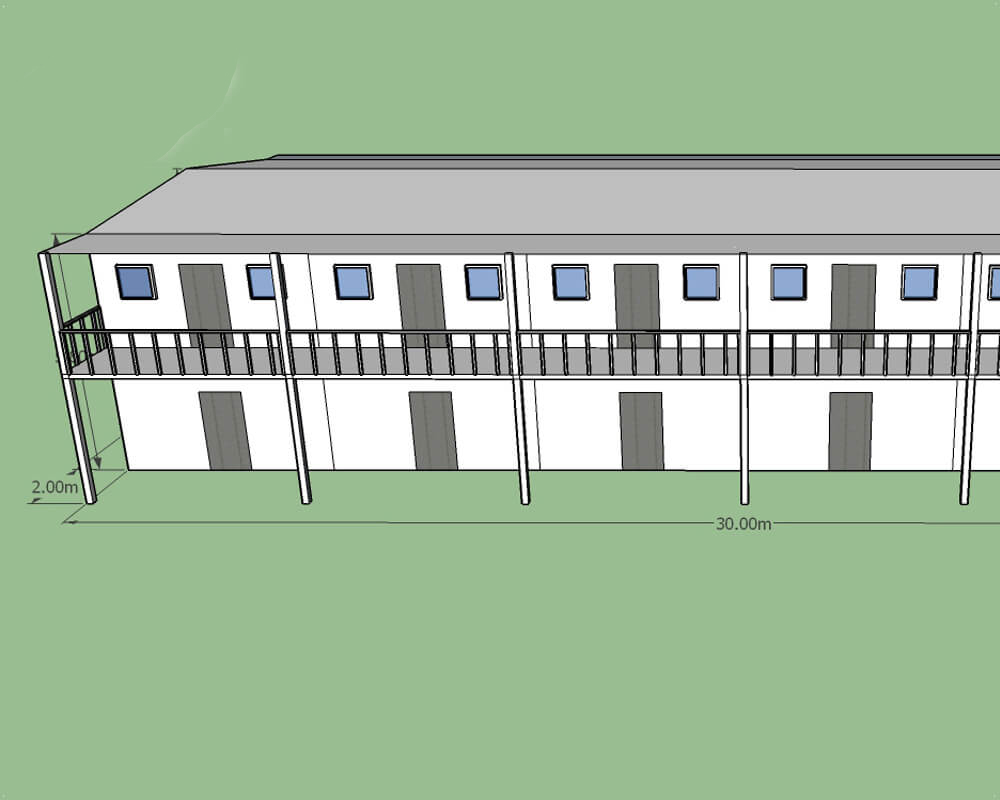

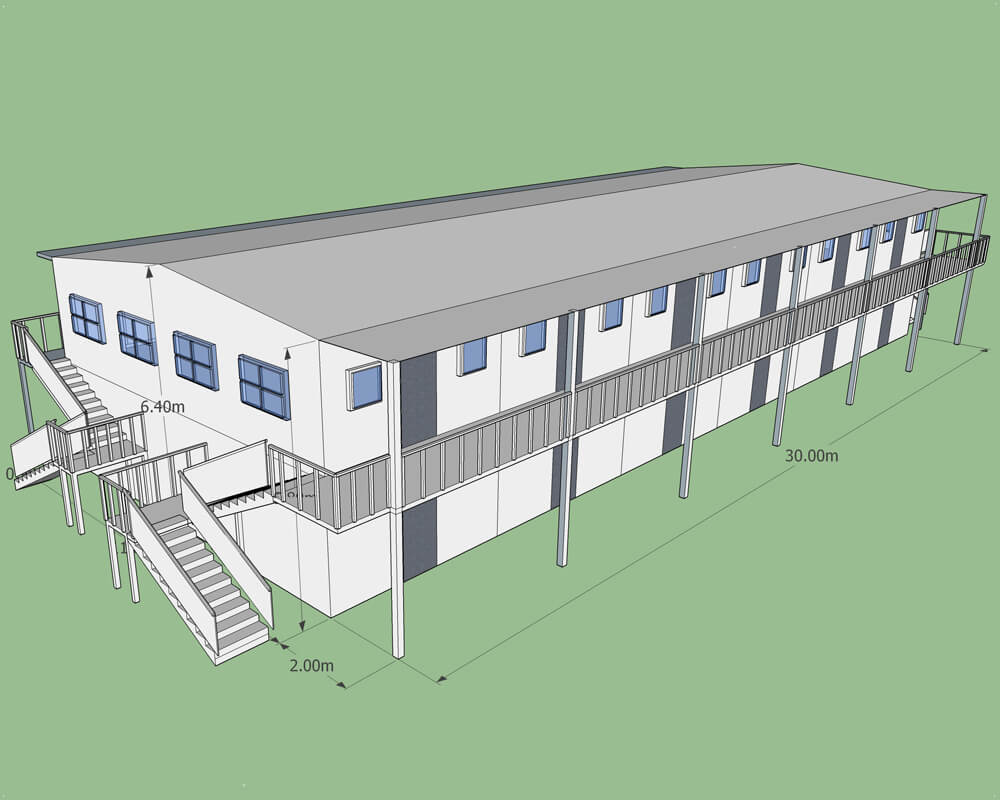

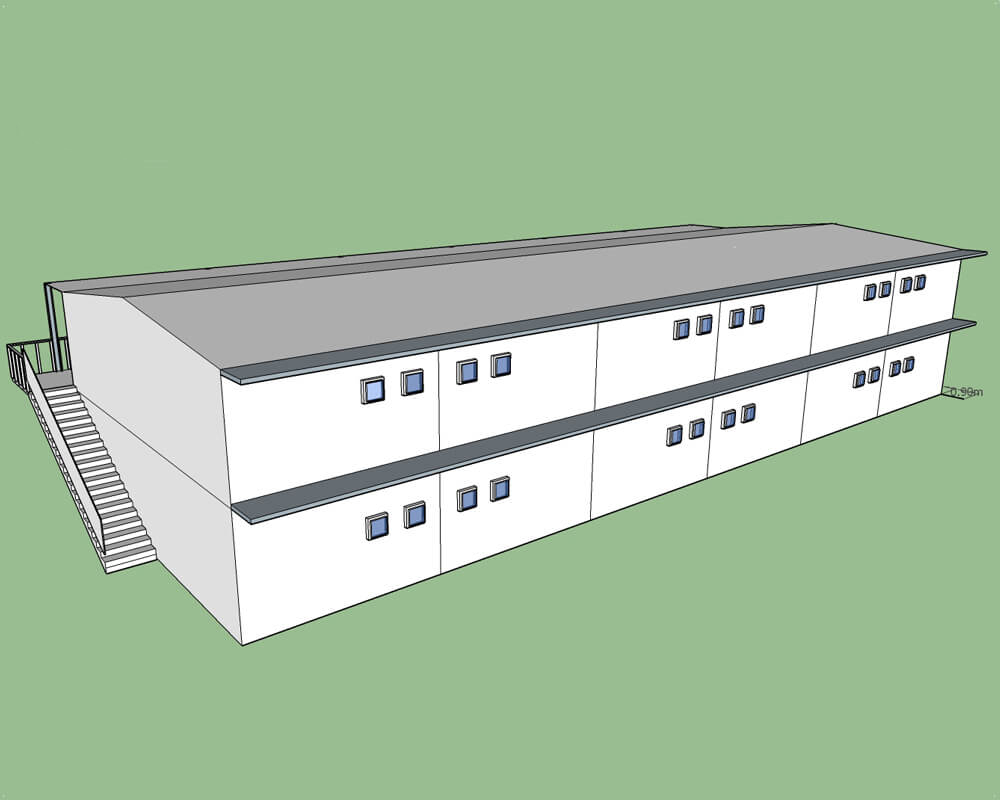

3. After project starting, we can provide a full set of design drawings (CAD drawings, 3D models) for customer to inspect and confirm.

Service

Pre-Sale Service |

|

Sale Service |

|

After-Sale Service |

|